Measure and display the amount of heat flow through building elements and their U value accurately, quicker and cheaper than ever before.

Making heat loss visible

Measure and display the amount of heat flow through building elements and their U value accurately, quicker and cheaper than ever before.

Here is a video with sound demonstrating how to use HEAT3D to capture an energy survey of a room in 1 minute

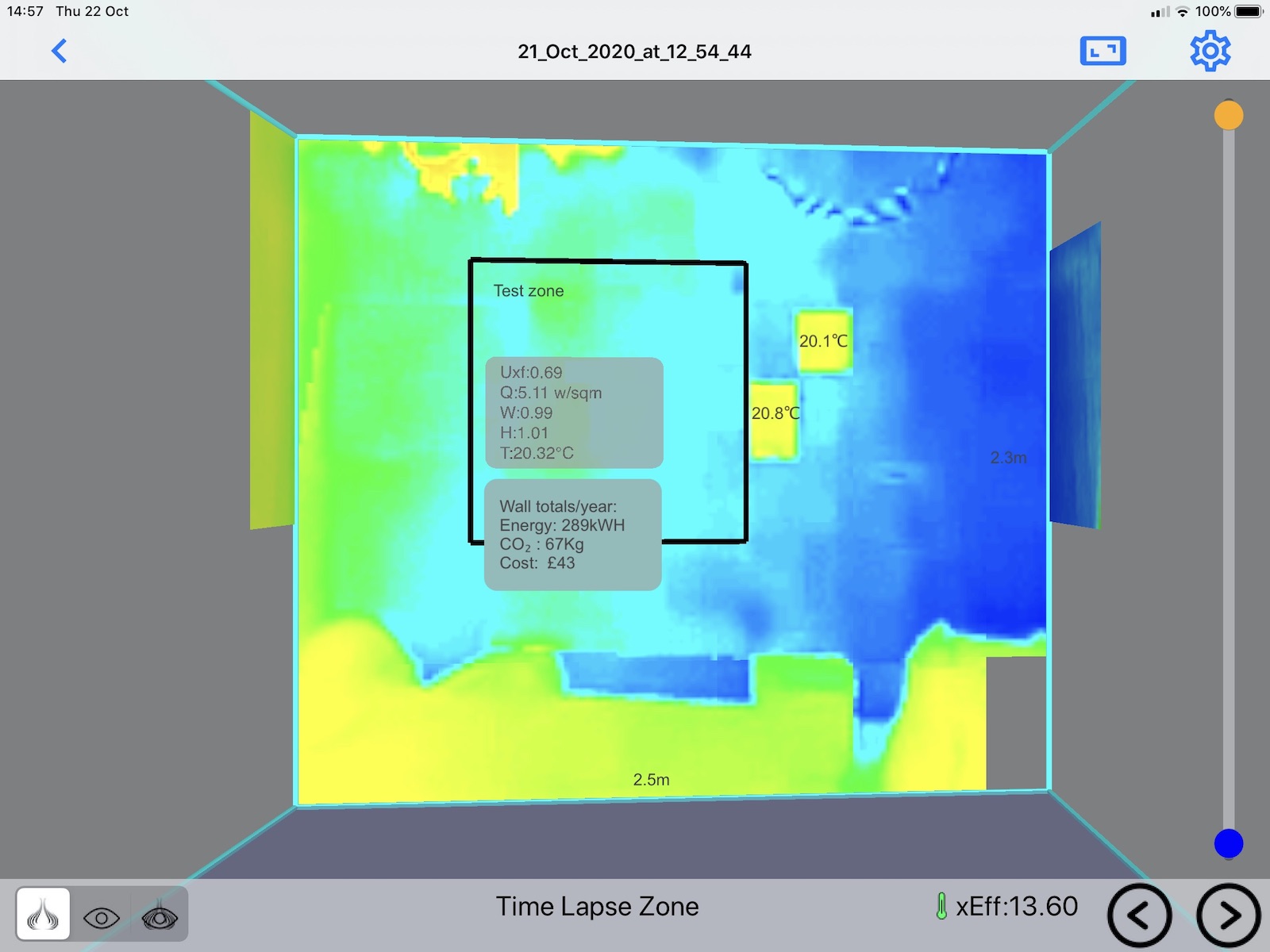

Use HEAT3D® to see the cost of the heat flowing through the fabric of a building. Work out where best to insulate and whether it’s worth it. If you live in a warm place measure the heat coming into the rooms and see how much air conditioning costs could be saved. Take a HEAT3D survey before and after adding insulation and measure the heat flow difference and true cost savings.

HEAT3D takes thermal imaging to the next level by measuring the amount of heat energy flowing through surfaces (in Watts or BTU/h). Its primary use is in buildings for heat flow in either direction through a surface – e.g. warming or cooling.

HEAT3D uses an innovative development of quantitative infra-red thermography, combining two new and inexpensive technologies to provide a low cost handheld instrument offering a quick and highly visual 3D measurement of the heat flux value through a building surface in watts, along with its U value. HEAT3D doesn’t just measure the IR temperatures, it accurately measures the actual heat flow in watts (BTU/h) flowing through each part of the surface. These measurements can then be used to provide accurate input for before and after measurement and comparison of U values during refurbishment of existing buildings to improve insulation, and to check a new building’s performance meets predicted/designed U and R value expectations, provides the expected return on investment and meets future domestic EPCs (Energy Performance Certificate) requirements.

The research and development behind HEAT3D was part funded by Innovate UK

Using HEAT3D saves thousands in the cost and impact of implementing energy-efficiency improvements for Westminster Abbey. The Westminster Abbey estate comprises a diverse range of buildings that are currently undergoing energy-efficiency improvements to reduce carbon impact and ensure resilience for future generations. The Grade I listed Deanery, for example, parts of which date back to …

Continue reading “HEAT3D saves thousands in cost of Westminster Abbey energy improvements”

The initial patent application for HEAT3D dating back to 2021 has now been granted:- “A method for generating, in real time, an interactive three-dimensional quantitative thermal heat flow mapping of an environment…” HEAT3D measures heat flow (e.g in watts) accurately through surfaces in real time. Initially deployed for measuring heat flow through building elements walls, …

HEAT3D was nominated for the Wales Technology Awards 2024 and won against some great competition. Hosted by BBC Wales news anchor, Jennifer Jones, the Awards ceremony gathered 300 of the brightest minds and most innovative companies in the Welsh technology industry, along with representatives and supporters across industry, public and private sectors. It celebrated the …