Using HEAT3D saves thousands in the cost and impact of implementing energy-efficiency improvements for Westminster Abbey.

The Westminster Abbey estate comprises a diverse range of buildings that are currently undergoing energy-efficiency improvements to reduce carbon impact and ensure resilience for future generations. The Grade I listed Deanery, for example, parts of which date back to the 13th century, stood out for its high energy consumption. With its thick masonry walls, timber panelling and original metal-framed windows, it was a good starting point for a data-driven assessment.

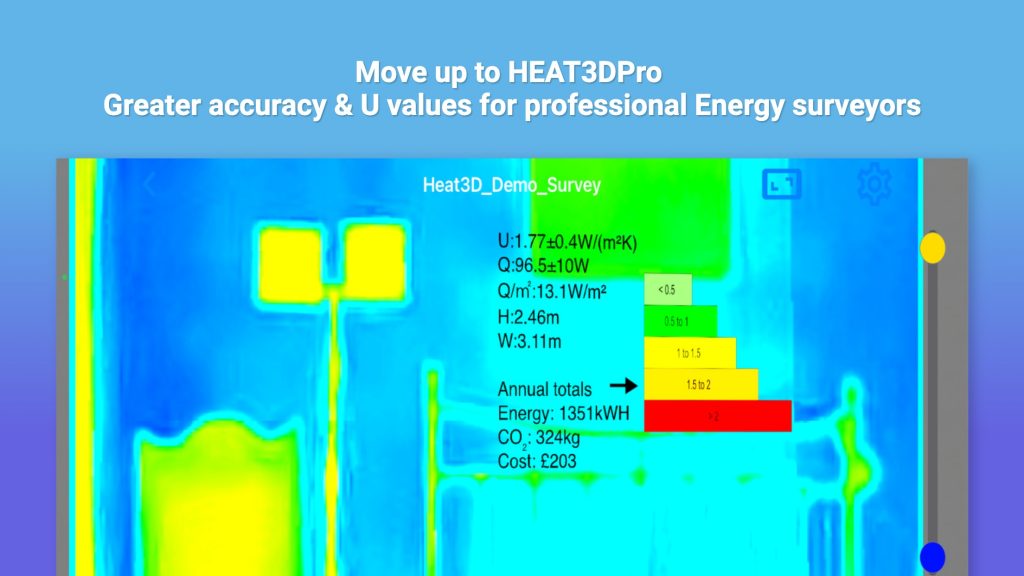

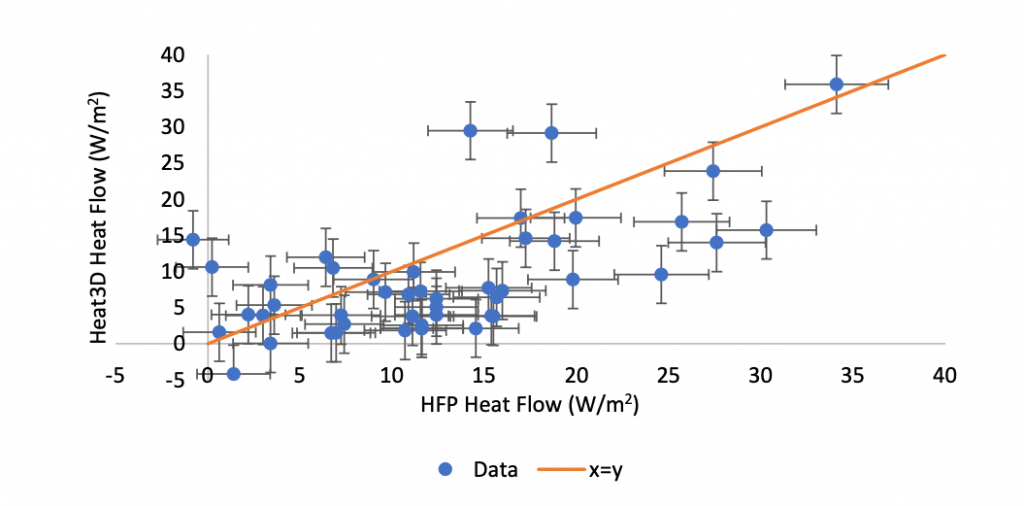

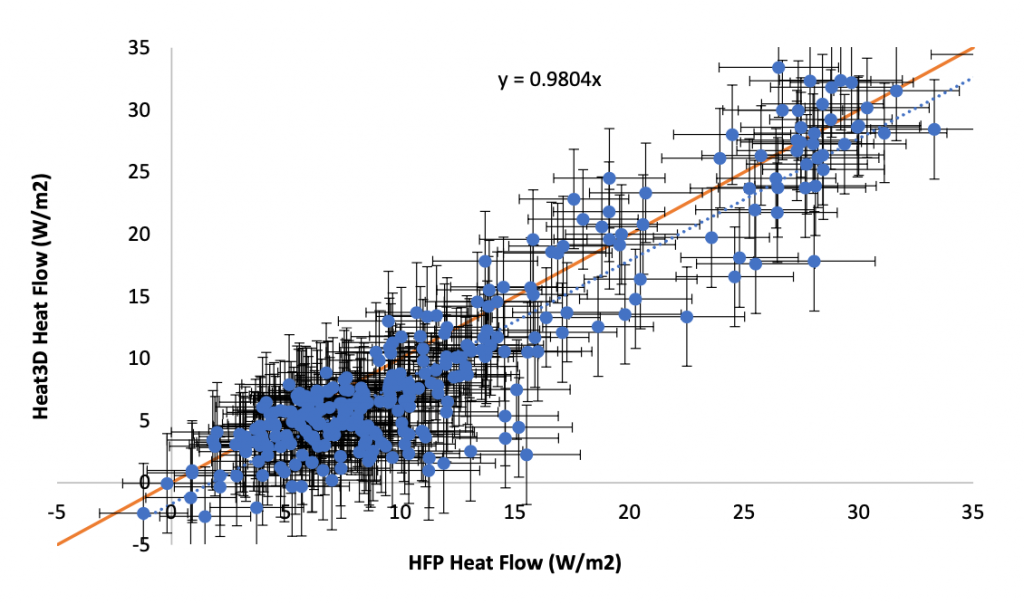

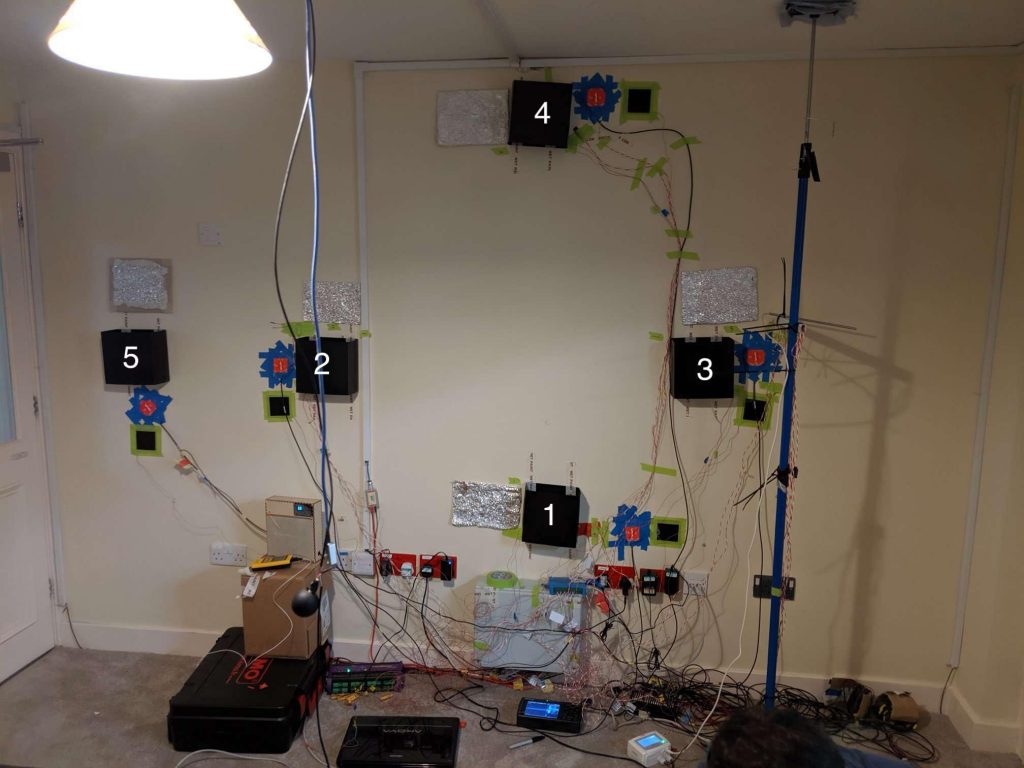

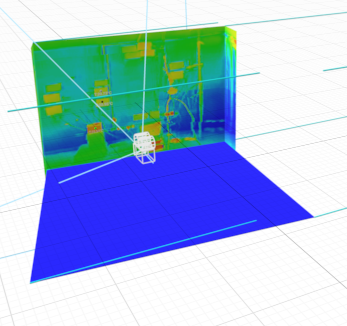

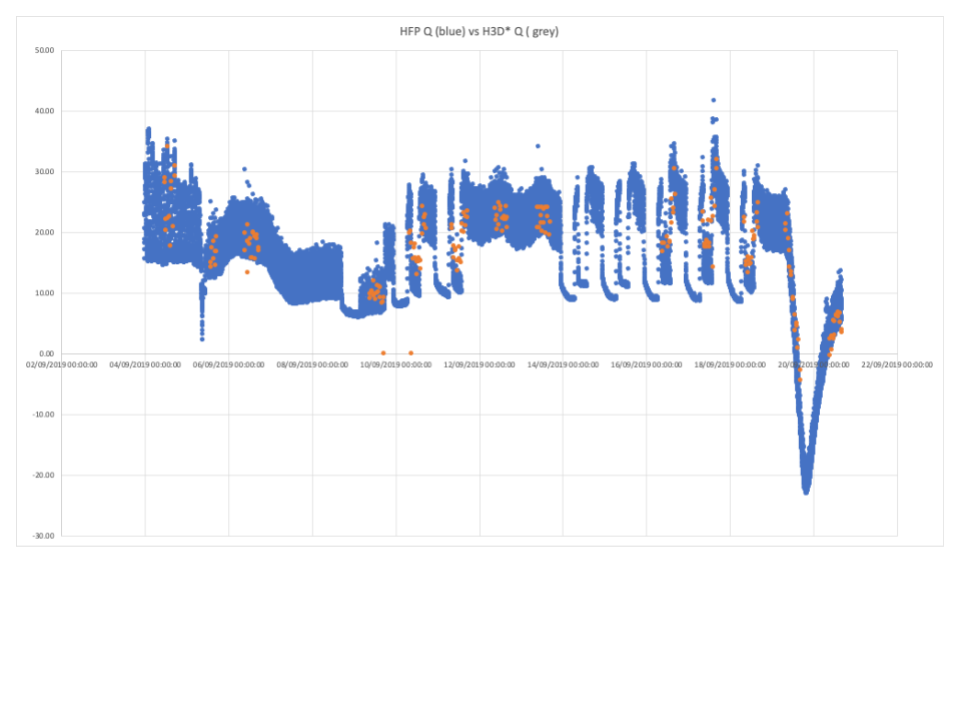

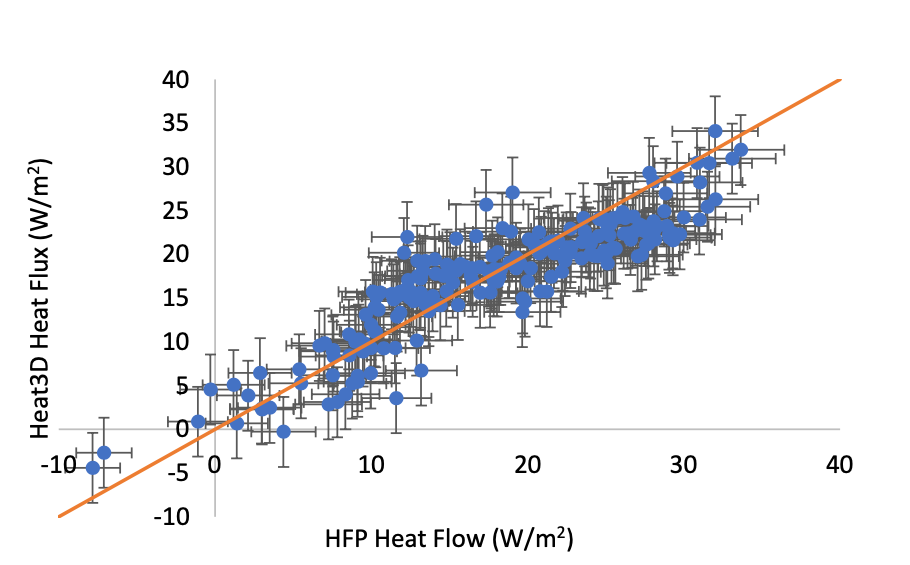

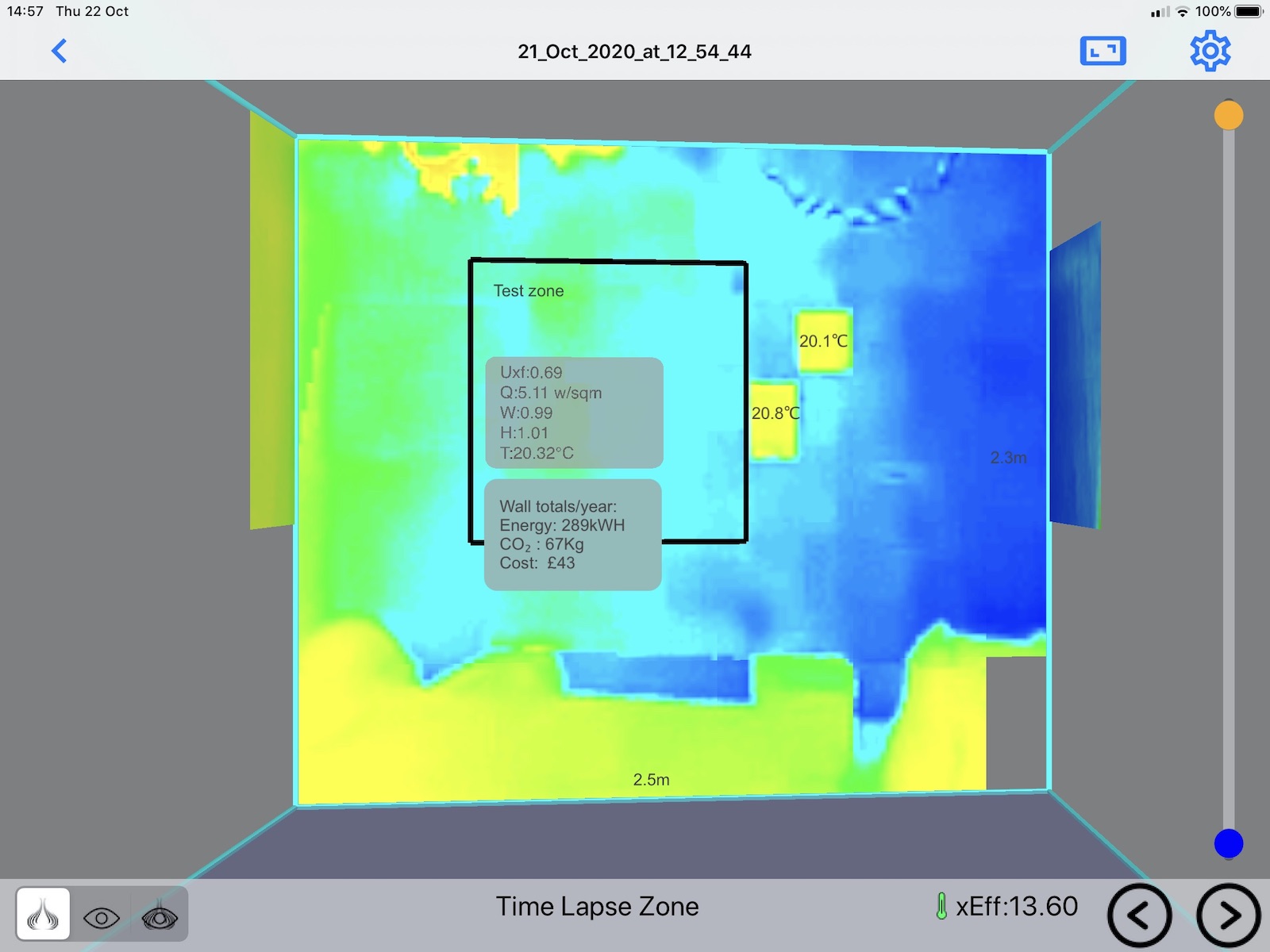

To understand the building’s thermal performance and conduct a detailed assessment, Westminster Abbey appointed multi-disciplinary property and construction consultant Keegans, which invested in Heat3D technology from BTS to measure the U-value of the main building’s brick walls, as well as the stone-walled extension.

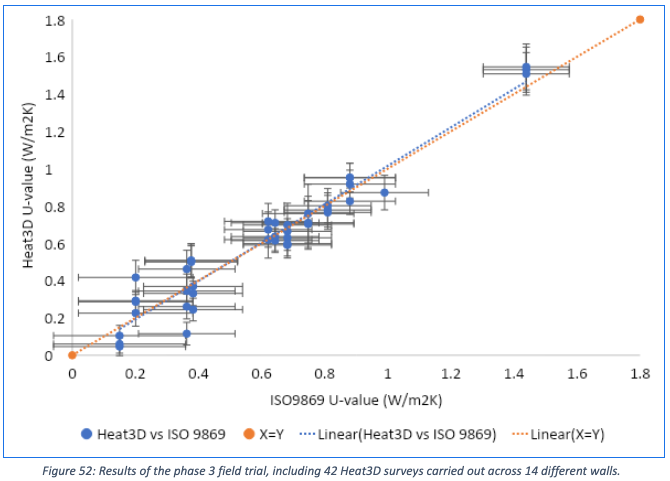

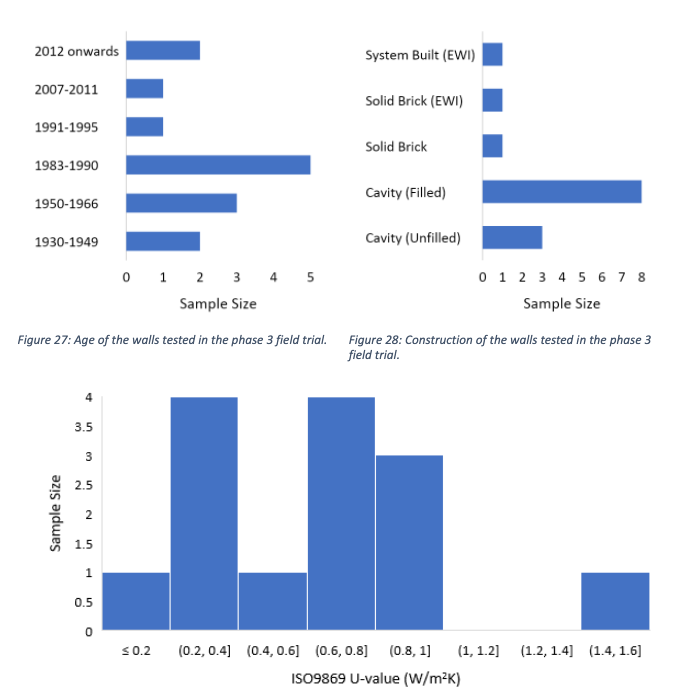

The results were surprising. The wall U-values were much lower [better] than assumed. For example, the predicted U-value for the main wall (rendered solid brick) was 1.7 W/m2K. The actual measured value was just 0.8 W/m2K, some 53% better than expected. Similarly, the predicted value for the 13th century fair-faced stone wall of the extension was 2 W/m2K, while the actual value was 0.9 W/m2K, a difference of 55%.

Beyond measure

By capturing more accurate measurements of U-values (and air permeability), surveyors can provide clients with more precise estimates of annual energy costs. In the case of the Deanery at Westminster Abbey, the calibrated model based on actual measurements provided a 16% more precise value for annual energy costs, equating to a financial difference in predicted savings of more than £1,000. This is just for one building. Westminster Abbey now plans to apply similar testing across its estate.

Crucially, the insight enabled Westminster Abbey to be confident that investing in upgrades such as secondary glazing, better heating controls and targeted draught-proofing would prove a cost-effective yet sufficient option compared with installing internal insulation, which the measurements confirmed were unnecessary.

“It essentially allowed the management team to enhance efficiency without compromising the historical integrity of the Deanery,” explains Luke Smith. “Without this data it would have been easy to recommend changes that were costly, disruptive and unnecessary. With its lavish internal panelling, cornices and skirting, and ornate stone exterior, it could have cost tens of thousands of pounds just in refurbishing the building’s fabric following the installation of insulation.”

You can read more about HEA3D and Westminster Abbey here https://engineering-update.co.uk/2025/09/11/flir-one-pro-camera-aids-step-change-in-quantifying-the-thermal-performance-of-buildings/

HEAT3D was nominated for the Wales Technology Awards 2024 and won against some great competition.

HEAT3D was nominated for the Wales Technology Awards 2024 and won against some great competition.