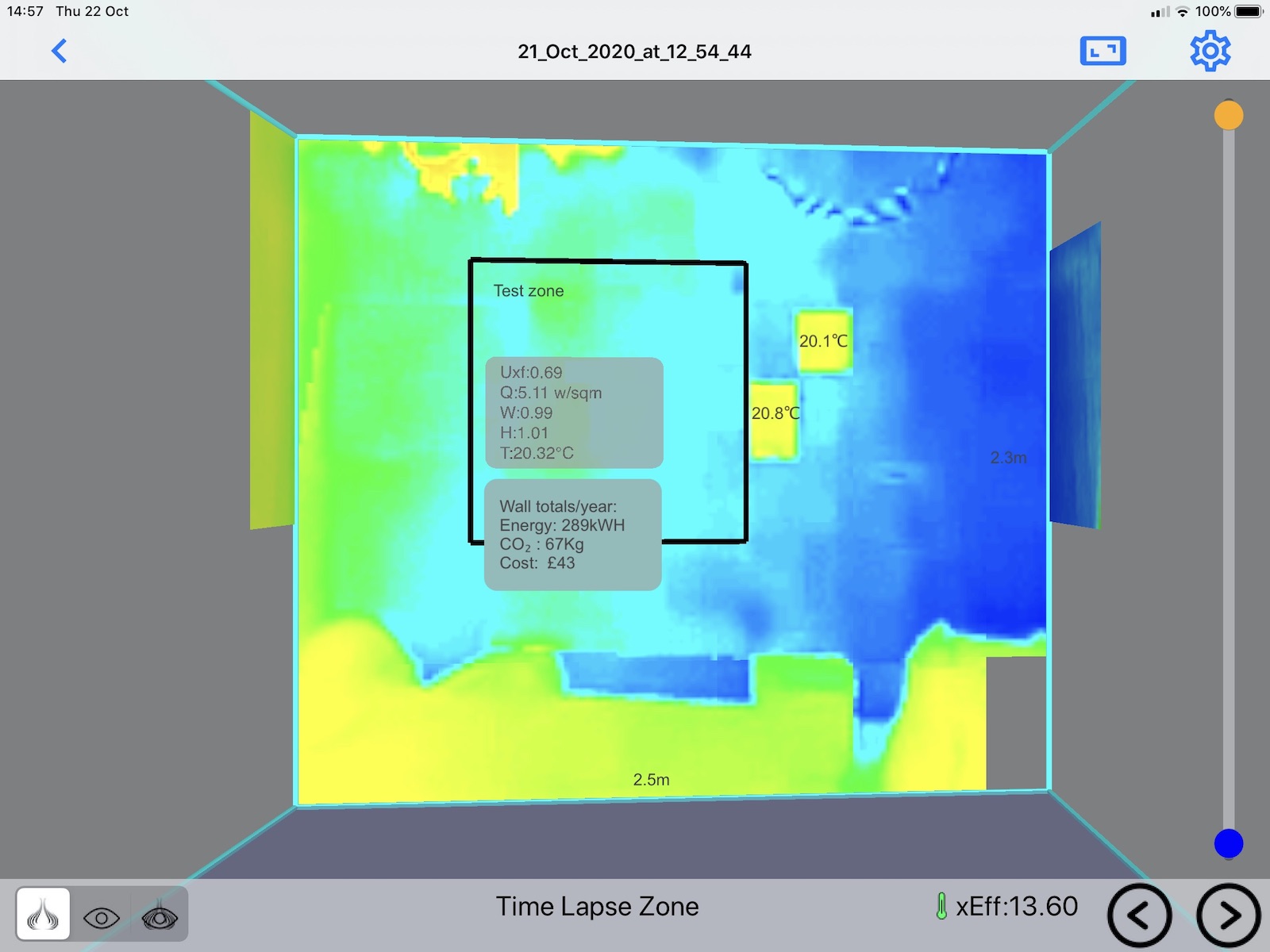

HEAT3D has been proved to measure U values accurately. Field trials have been carried out using HEAT3D’s innovative and unique time lapse survey procedure which takes less than an hour resulting in U-value measurements across a whole wall surface. This improves upon two key limitations of the existing standard method using heat flux plates, the length of the measurements (ISO9869 requires at least 72 hours and two visits to site) and their limitation to only the small area covered by the sensor. Heat3D therefore enables a less disruptive, more insightful and cost-effective testing method. The measurements were compared with ISO9869 measurements of the walls taken at the same time.

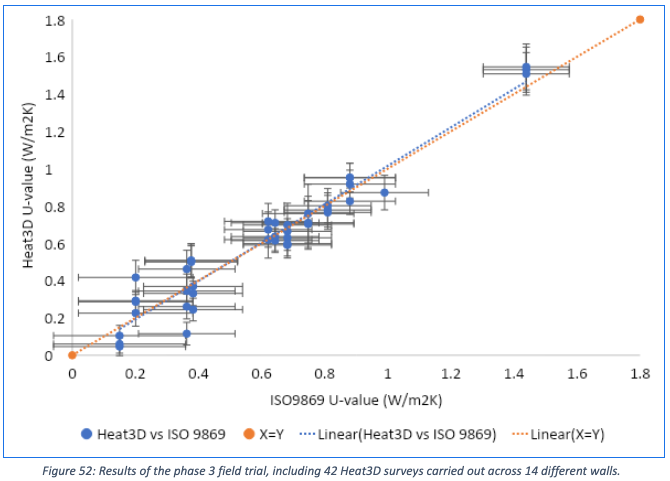

The results are very positive, with a close and direct relationship between the measurements by Heat3D and by heat flux plates according to ISO9869. In total 42 Heat3D surveys were compared with an ISO9869 U-value measurement across 14 different walls. In 36 of the surveys the U-value measurement by Heat3D fell within the combined uncertainty interval of the ISO9869 measurement. There was very close agreement between the two methods for U-values above 0.2W/m

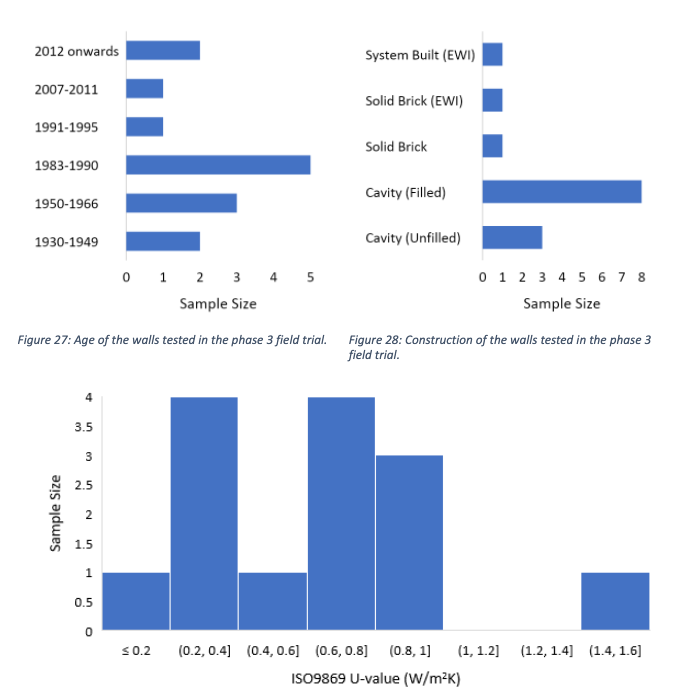

The surveys were carried out across a wide range of locations around England and Wales with one property measured before and after the application of additional external wall insulation.

A range of building ages were surveyed with the majority of tests carried out on cavity walls

A detailed validation report is available. For more information please email us at:- business@electricpocket.com